Product Description

Product Description

Our company produces “Anniu” brand rice hulling rubber roller using NBR imported materials, using imported reinforcing resin and imported silica reinforcement, the product is pollution-free, does not contain formaldehyde. It has moderate hardness, good elasticity, high tearing strength, small permanent deformation and high wear resistance. It is a high-quality new style rubber roller. Generally, the service life is two to three times longer than common rubber rollers in the market, our rubber roller has good elasticity and low broken rice rate, so please feel free to use it.

Technical specifications:

Tensile strength:cm2 56.6Mpa

Tensile elongation: 240%

Hardness (shore A): 94 -95°

Permanent deformation: 2%

Akron abrasion: 1.63km/cm3 0.015

Our company produces “Anniu” brand rice hulling rubber roller using SBR domestic material, using imported reinforcing resin and imported silica reinforcement, the product does not contain formaldehyde, it is pollution-free, translucent, and has good elasticity, high tearing strength, high wear resistance, moderate hardness, high hulling rate, low broken rice rate. It is a new type of rubber roller and please fell free to use it.

Technical specifications:

Tensile strength: cm2 42Mpa

Tensile elongation: 260%

Hardness (shore A): 94 -95°

Permanent deformation: 1 .5%

Akron abrasion: 1.63km/cm3 0.05

Detailed Photos

Product Parameters

Packaging & Shipping

Company Profile

HangZhou QUANSHENG CZPT MACHINERY CO.LTD is a modern science and technology enterprise integrating R&D, design, production, selling and services. Our company developed the rice hulling rubber roller, which obtained the national patent in 1998, patent number: ZL98 315711.0. In 2012, we upgraded it again, using new technology, new formula and new process, developed “Anniu” brand Rice Hulling Rubber Roller, which is semi-transparent, high abrasion resistance, high strength, high elasticity and low broken rice rate, and is the first-class product in domestic and abroad. Our products are sold very well in our country and exported to South Asia, Southeast Asia, Latin America, Africa and other countries and regions, and are widely accepted by Domestic customers and Foreign Customers.

Our company always adheres to the business philosophy of “quality for survival, technology for development, service for credibility, management for efficiency”, and follows the tenet of “professionalism, integrity, service, innovation, quality, efficiency”, and is dedicated to providing excellent quality products and first-class services to customers in domestic and abroad. We warmly welcome customers to visit our factory to discuss business, let us work together to create brilliant achievement!

Our Advantages

ANNIU brand Rubber Roller made up with it’s latest technology combined with its superior chemical formulation as made by our research and design teams gives an utmost performance which is far ahead from any other brand in the industry.

1.We are an ISO-9001 Certified Rubber Roller Company.

2.Manufactured with most advanced plant and care it gives trouble – free shelling without any air bubble problem.

3.Due to its innovative chemical formulation, our products can stand high degree of heat.

4.Our Rubber Roller goes through number of tests before it reaches to our customers.

5.Each piece it thoroughly checked also in final stages before it is packed relating to its Dimensions.

6.It is our SUPERB product which has no match in the market.

7.It is the best quality rubber roller available in our country. It gives highest output of rice with least broken of rice.

8.We have ensured optimum efficiency for a longer time period of Rice Rubber Rollers.

9.It solves dual purpose- highest output lowest broken of rice.

10.It is manufactured with best United States high nitrile rubber and German rubber chemicals

50-60% more output than other rubber rollers & also guaranteed least broken of rice than others.

11.Our sophisticated product ensures better life of your expensive machines.

12.Almost 0% rejection and replacement.

FAQ

Q1.What’s your advantage? Why we choose you?

A: 20 Years experience of research,design and manufacture of rubber rollers. We have the most professional techniques and team.It is a young, innovative and elite research and development team and has a strong ability in innovation and creation. we provide our customers with competitive price and excellent quality products.

Q2.What’s the Payment?

A:T/T would be better with quick transfer and few bank fees. L/C could also be accept, but the procedure is complex and the fee is high.

Q3.Are you a factory or trading company?

A:We are a professional manufacturer focusing on rubber rollers for more then 20 years. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4: How do you make QC control?

A: We have 10 inspectors inspect from raw material, sample, operation, semi-product to final product.

we use much better raw material and we have most advanced production line which was imported from German only last year. we has included better quality control policy. Third party inspection and production and shipment monitoring.

Q5: Are customized and small order available?

A: Yes, samples or drawings are enough. Either 1pcs or 10000 pcs are available.

Q6: How many workers in your factory?

A: We have nearly 300 workers and 80% of them have been working for us over 5 years.

Q7: What kind of certificate you have ?

A. Our company already achieve ISO9001 certificates, SGS certificate and many test reports.

Our products also have 11 patented technologies.

Q8: What else can I do for you?

A. Our salesmen will reply your inquiry within 24 hours. We can give you any support on the technique & other aspects.

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Material: | NBR /SBR |

|---|---|

| Usage: | Paddy Hulling Rubber Roll |

| Roller Surface Material: | Rubber Roller |

Agricultural Parts

Agricultural machinery, also known as agricultural machinery, is any mechanical device or structure used in agriculture . It includes hand tools, tractors and countless other farm implements. Agricultural machinery can be divided into two categories: power tools and hand tools. Some of the most common types of agricultural equipment are listed below. Each of these categories includes parts used to repair, maintain, and operate a specific piece of equipment or machinery. To learn more about agricultural machinery, please visit the Manufacturers and Suppliers section of our website.

Agricultural Machinery

Agricultural machinery parts are critical to the overall operation of a farm or ranch. Replacement parts are essential if your equipment is not functioning as expected. CZPT’s consumables experts are ready to help you find the right replacement parts for your equipment. You can rely on our knowledgeable staff to provide you with fast and accurate replacement services. If your agricultural machinery needs replacement parts, please contact us for assistance.

Key drivers of the agricultural machinery market include high global demand for food, rapid crop production, access to resources, and availability of credit. Agricultural machinery is mainly manufactured in Europe, the United States, Japan and China. Overall, we expect the agricultural machinery market to exceed $118 billion by 2025. Additionally, agricultural machinery OEM components are expected to grow at a CAGR of 3.6% over the next five years.

Agricultural machinery accessories include accessories and accessories other than tractor accessories. Plows loosen the soil and kill surface vegetation, fertilizer spreaders apply fertilizer evenly, rakes agitate the soil, and seeders sow seeds. Other accessories include balers, which collect materials and bundle them into management packs. Transplanters are used to transplant plants from one location to another. It must be properly maintained to maximize its useful life.

Farm machinery accessories can be found in all types of farming. From sowing to harvesting, farm machinery equipment is necessary to help farmers in various agricultural activities. Without mechanization, farming would not be as profitable as it is today. In Iran, CZPT produces agricultural machinery parts including harrows, tillers, grain refiners, spinning machines and threshers. You can also find farm machinery accessories for sale through these companies.

A well-known brand in the field of agricultural machinery is CZPT. Parts can be found for CZPT and CZPT models. The company also produces replacement parts for many different models. The company’s extensive dealer network spans more than 160 countries. PDF also supplies agricultural machinery parts for brands such as Ford and CZPT. If you are looking for reliable quality and cost-effective agricultural machinery, we can get the parts you need from these brands.

Agricultural Equipment

Growing population and demand for equipment drive the demand for agricultural equipment in Asia. In countries with limited land such as India, low-paying agricultural jobs are not enough for many farmers. At the same time, Australia has a large amount of agricultural land, but the reduction of agricultural labor has led to the increasing mechanization and integration of agricultural production. This, in turn, has fueled a surge in demand for Australian agricultural products in Asia, particularly in China and India.

Tractor transplanter is a common agricultural equipment. Tractors pull on these machines, which dig holes and put plants into the holes. A cultivator is another type of agricultural equipment that tills the soil and controls weeds. Smaller operations often use a cultivator. Large plastic farms, on the other hand, need to invest in cladding, using a series of wheels to lay down a layer of plastic.

Agricultural machinery is widely used. For example, tractors can carry heavy agricultural attachments such as haymakers and grain turbines. Farm equipment also helps farmers prepare soil for growing and harvesting large quantities of crops. It also helps transport food to other regions for processing. These machines make farming easier and more efficient. With all these benefits, it’s no wonder so many people engage in farming as a profession. The world needs food and agriculture, and agricultural equipment is an integral part of the process.

Agricultural equipment operators use heavy agricultural machinery every day. They inspect the equipment and make minor repairs to keep it running smoothly. They also monitor the working environment and working conditions around the equipment. Depending on the field, agricultural equipment operators can operate a variety of agricultural equipment, load and unload products, and even harvest crops. These workers may spend most of the year working outdoors, which can take a long time. The average workweek for an agricultural equipment operator is approximately 18 hours.

Agricultural equipment operators often gain practical experience on the job. Some jobs in the industry may require a high school diploma, and students without a high school diploma can work on farms to learn the skills needed for the position. The industry requires employees to be properly trained and certified to operate equipment safely. AWS certification is highly recommended. All Associate of Applied Science in Agricultural Production Systems include core business and management courses applicable to the agricultural industry.

Agricultural machinery manufacturers

Agricultural machinery manufacturers produce agricultural implements such as tractors and combines for agricultural purposes. The production of these machines increases the productivity and efficiency of farmers around the world. These machines and parts increase the quality and quantity of crop production while reducing labor costs. They also help improve soil fertility. It’s important to choose the right type of machine for your farm because not all farm machinery is the same. There are many high-quality agricultural machinery manufacturers in China, whose prices are competitive with the local market prices.

The growth of the agricultural machinery market is mainly driven by the growing global food demand. Agricultural equipment manufacturers are investing in precision-based technologies, which allow them to build better agricultural machines. In addition, OEM parts manufacturers focus on the safety, quality and continuous improvement of agricultural machinery parts. With the shift in focus, the agricultural machinery market is expected to make great strides in the coming years. Along with these improvements, the demand for agricultural machinery OEM parts is expected to grow at an annual rate of over 3%.

CZPT Group: This agricultural machinery manufacturer has more than 20 overseas service centers around the world. The company is committed to providing excellent customer service and provides a warranty on all of its products. CZPT Machinery’s space parts are easily available at their service center. Shandong CZPT Heavy Industry International, a Chinese agricultural machinery manufacturer, was established in 1998 and is headquartered in Weifang City, Shandong Province.

Although the agricultural machinery industry is growing, the market is still affected by the economic downturn. The COVID-19 pandemic has put pressure on farming operations, who may forgo buying expensive equipment. Private investment in industrial equipment is also falling and is expected to decline further in 2020 and 2021. On the other hand, aftermarket agricultural machinery parts are tailored for an exact fit and outperform OEM parts.

Agricultural Machinery Suppliers

Agricultural Machinery Suppliers have a wide variety of products. From large farm machines to small ones, you’ll find it all in one place. In addition to providing first-class machinery, agricultural machinery suppliers can also provide you with spare parts. Shandong Heavy Industry International, for example, is China’s largest agricultural machinery maker, with annual sales of $9 billion. The company is headquartered in Weifang, Shandong and has been operating for more than six years.

Most farm equipment consists of hundreds of parts. For example, a typical tractor has more than 1,700 parts. Manufacturers have been shifting to just-in-time delivery of parts and raw materials. While the system works for predictable supply chains, it can break down when one component fails. Therefore, the best way to avoid problems and maximize profits is to get a list of Indian agricultural machinery suppliers through a dedicated marketplace.

Therefore, there are many suppliers of agricultural machinery. Some of the biggest names in the industry include CZPT and CZPT, both of which employ thousands of people. CZPT also offers a complete line of walk-behind and riding mowers, as well as log splitters and snow blowers. In addition, the German-made CZPT tractor line is being launched in Brazil. Finally, some smaller agricultural machinery enterprises produce and sell agricultural machinery.

In the next decade, the global agricultural machinery market will grow moderately. But in the short term, crop prices are expected to fall, which will negatively affect agricultural income and the agricultural machinery market. Experts predict that this will affect the demand for agricultural machinery. These factors will continue to influence the market and help farmers make better decisions. However, no single factor can guarantee that the agricultural machinery industry will not be affected by economic changes.

In addition to tractors, other types of agricultural machinery are also widely used for agricultural purposes. Tractors are the most common type of agricultural machinery and include rotary tillers, power tillers, subsoilers and trowels. Other equipment used for planting includes planters, planters and irrigation systems. Some specialized equipment includes sprinkler systems, micro sprinklers, and soil spray technology.

editor by CX 2023-05-26

China manufacturer High Quality Sand Molding Line Produce Agricultural Machinery Spare Parts near me supplier

Item Description

ZYD has 18 years’ manufacturing encounter.We could help customer design and style the mould and offer valued tips to lessen fees for client.If you have a minute, you can check out our website underneath.

zhongyide

Since its institution in 2001, ZYD has often adhered to its administration concepts of “individuals first, very good faith, exceptional high quality and pioneering innovation”. After practically 20 many years of constant development, ZYD has grow to be a professional supplier of mechanical areas, masking an region of virtually 50000 square meters and CZPT an yearly productivity of over ten thousand tons. Having transformed from traditional casting to the integration of merchandise design, casting, processing and inspecting, ZYD keeps satisfying each customer’s expectation and necessity by virtue of its continuously improved manufacturing capacity.

Our Manufacturing facility

| 1) 18 years’ production experience | |||||||||||

| 2) could help customer design the mold and offer valued suggestions to reduce costs for customer | |||||||||||

| 3) PPAP documents is available if needed. | |||||||||||

| 4) OEM is welcome | |||||||||||

| 5) ISO9001:2015 certificate, ISO14001:2015 certificate, OHSAS18001:2007 certificate | |||||||||||

| Detailed Features: | |||||||||||

| 1. Material: | gray cast iron, nodular cast iron, austempering ductile iron (ADI, CADI), carbon steel, alloy steel, cast aluminum | ||||||||||

| 2. Casting Method: | clay sand casting, resin sand casting, lost wax precision casting | ||||||||||

| 3. Heat Treatment Process: | annealing, tempering, normalizing, induction hardening | ||||||||||

| 4. Machining Process: | turning, milling, grinding, drilling, inserting, broaching, boring, polishing | ||||||||||

| 5. Surface treatment: | anti-rust liquid&oil, painting, powder coating, zinc plating, hot-dip galvanization, phosphating, dacromat, thick-layer passivation( salt spray t0est 240hours), Ni plating, Cr Plating, etc | ||||||||||

| 6. Product Inspection: | 100% quality control | ||||||||||

| 7. Packaging: | plywood cases, cartons, steel pallets, etc. | ||||||||||

| 8. Lead time: | 30~40 days | ||||||||||

| 9. Terms of Delivery: | FOB Qingdao, CIF XXX | ||||||||||

| 10. Place of origin: | Gaomi, China | ||||||||||

| 11. Drawing & Software: | CAD, UG, PDF, JPG, ProE, etc. | ||||||||||

| 12. Application: | agricultural machinery, trucks, machine tool equipments, hydraulic pressure and pump devices, and some other fields | ||||||||||

| 13. Productivity: | over 10000 tons | ||||||||||

| 14. Export Markets: | Germany, Britain, Italy, America, Canada, Japan and some other foreign countries | ||||||||||

| 1) 18 years’ production experience | |||||||||||

| 2) could help customer design the mold and offer valued suggestions to reduce costs for customer | |||||||||||

| 3) PPAP documents is available if needed. | |||||||||||

| 4) OEM is welcome | |||||||||||

| 5) ISO9001:2015 certificate, ISO14001:2015 certificate, OHSAS18001:2007 certificate | |||||||||||

| Detailed Features: | |||||||||||

| 1. Material: | gray cast iron, nodular cast iron, austempering ductile iron (ADI, CADI), carbon steel, alloy steel, cast aluminum | ||||||||||

| 2. Casting Method: | clay sand casting, resin sand casting, lost wax precision casting | ||||||||||

| 3. Heat Treatment Process: | annealing, tempering, normalizing, induction hardening | ||||||||||

| 4. Machining Process: | turning, milling, grinding, drilling, inserting, broaching, boring, polishing | ||||||||||

| 5. Surface treatment: | anti-rust liquid&oil, painting, powder coating, zinc plating, hot-dip galvanization, phosphating, dacromat, thick-layer passivation( salt spray t0est 240hours), Ni plating, Cr Plating, etc | ||||||||||

| 6. Product Inspection: | 100% quality control | ||||||||||

| 7. Packaging: | plywood cases, cartons, steel pallets, etc. | ||||||||||

| 8. Lead time: | 30~40 days | ||||||||||

| 9. Terms of Delivery: | FOB Qingdao, CIF XXX | ||||||||||

| 10. Place of origin: | Gaomi, China | ||||||||||

| 11. Drawing & Software: | CAD, UG, PDF, JPG, ProE, etc. | ||||||||||

| 12. Application: | agricultural machinery, trucks, machine tool equipments, hydraulic pressure and pump devices, and some other fields | ||||||||||

| 13. Productivity: | over 10000 tons | ||||||||||

| 14. Export Markets: | Germany, Britain, Italy, America, Canada, Japan and some other foreign countries | ||||||||||

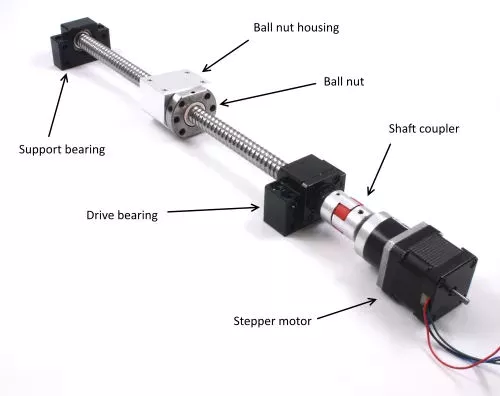

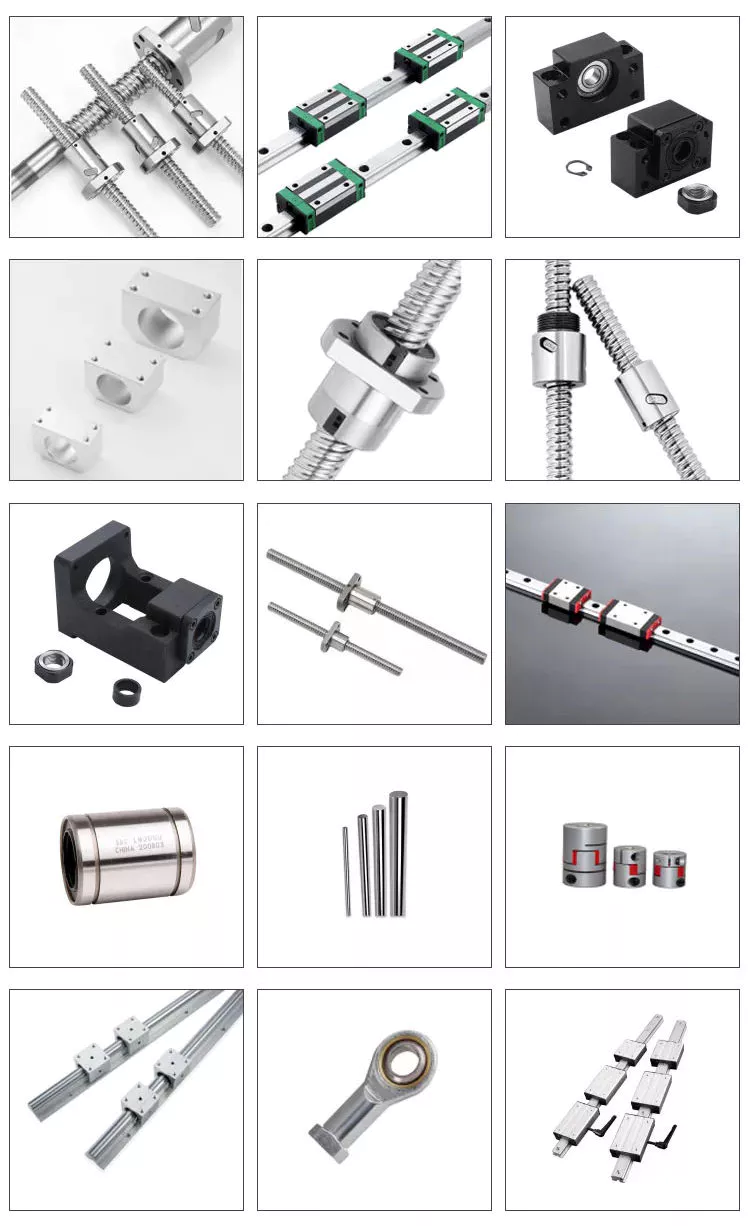

Supporting Ball Screws

In order to use a ball screw in a project, it is important to support it for rotation. Typically, this requires holding brackets and roller bearings. Longer screws may require bending or critical speed restraints. End machining may be necessary to fit the screw into the bearing. Connection to a motor requires coupling and appropriate machining. Tables or support rails may be necessary to restrain the nut.

Cost

In this report, you’ll get an in-depth analysis of the ball screw market. You’ll learn about the competitive landscape, product portfolio, and growth prospects across regions. The report will also include information on the market’s various drivers and restraints, as well as the factors driving or restraining its development. You’ll also get an in-depth look at the value chain and PEST analysis, which are important components of a market study.

One resource that you can use to research the Ball Screw market is CZPT. This website contains a database of authentic Indian manufacturers, suppliers, and importers. You’ll find contact details and email addresses of the companies, including those that produce a wide variety of different types of ball screws. CZPT even allows you to search by product category. That way, you can find a supplier based on the type of ball screw you need at the lowest price.

Another benefit of ball screws is their ability to operate in very delicate applications. In electric vehicles, they are often used to replace a common hydraulic system. They are also used to control gates at hydroelectric stations. You can also find them in motorised inspection tables, step photolithography machines, and microscopic integrated circuits. You can find hundreds of different ball screw designs, and you can even purchase them with nuts, wipers, and CZPT. Ball screws have several bearing balls, which help transfer load between nut and screw. They can be available with adjustable preload and non-preloaded options. And they’re manufactured to industry standards to meet the demands of their users.

If you’re looking for a reliable, high-performing screw, you’ll want to opt for a ball screw. These have high performance-to-cost ratios. You’ll need to choose between a lead screw and a ball screw, but both are reliable and efficient. Besides, the former is less expensive and offers great design flexibility. They’re corrosion-resistant and can even be self-locking for vertical applications.

Applications

A ball screw and nut assembly are essential components of a variety of important actuation and control devices. The two components rely on the ability of the screw to rotate easily while converting the rotation into precise lateral movement. Ball screws are a common component in computer-controlled motion-control systems. The precision of ball screw rotation is essential for the accurate adjustment of flight control surfaces. In addition, ball screws are important components of wire bonding and computer-controlled motion-control systems.

Ball screws are highly accurate, requiring minimal lead error. The lead error of a screw is the difference between the theoretical and actual distance traveled by the nut during rotation. The lead error of a ball screw depends on several factors, including the manufacturing accuracy of the ball grooves, the compactness of the assembly, and the set-up precision. This error is not constant from lead to lead, but it may be reduced through preloading, lubrication, and increased mounting accuracy.

The ball is urged to move up and down by rotation of the nut, which is preferably a hexagonal shaft. This allows the ball to be raised easily over the land of the screw. It is important to note that the nut has a groove on the outer surface that is deep enough to accommodate a ball. This groove is deep enough to accommodate a ball, and the groove extends the length of the screw, thereby reducing friction and increasing precision.

The recirculated balls in a multi-start ball screw assembly may cross multiple threads and turn in the circuit. Multi-start ball screw assemblies typically use the internal channel method to recirculate balls. This design allows multiple ball nuts to be used in a single nut and can be easily installed. The ball nut and the nut may also be incorporated into several separate circuits. If several recirculation paths are desired, a ball nut and a multi-start system may be used.

Durability

A key feature of ball screws is their durability. During manufacture, a ball screw’s material must be chosen carefully. A corrosion-resistant steel called Cronidur(r) 30 is an ideal choice. Ball screws made from this material are exceptionally reliable in space due to their alternating steel-ceramic architecture. As the conditions of space are extreme, corrosion-resistant materials are essential to ensure optimum performance. CZPT has decades of experience manufacturing high-quality ball screws. Besides providing a complete range of ball screws, the company also offers technological solutions and dedicated components.

CZPT developed a special design for the High-Durability Precision Ball Screw. This design makes it easier to form a thin film of oil on the material’s surface. This oil helps reduce friction and improve the precision of a ball screw. This material’s special microstructure reduces the wear of ball screws and improves their service life. CZPT also aims to improve the wear-resistance of ball screws.

In addition to the axial load, a ball screw’s life rating should be based on the jacking and vertical loads. In other words, if all load balls are in contact with the raceways, the L-10 life rating of ball screw assemblies would be converted to an L-2 life rating. This change would increase the overall reliability of a ball screw to 98%. Then again, it’s important to note that vertical load is the only one that would be completely removed from the chart.

In addition to these important considerations, it is essential to operate ball screws within their recommended operating temperature range. Failure to do so could result in thermal expansion of the ball screw, causing positioning errors. To ensure lubrication of the ball screw, it’s important to keep its operating temperature within the recommended range. However, it is possible to operate it at temperatures that are too high. If this occurs, the screw should be sent to the manufacturer for repair.

Size

Besides their obvious use, ball screws come in two sizes, large and small. Although small balls should not show significant wear, they should still be used to enhance the screw’s durability. This can be difficult to determine because screw rebuilders tend to overlook this aspect. So, what is the best size for ball screws? This article will look at both sizes and what they mean for the screw’s durability. Also, we’ll look at some of the things to keep in mind when choosing the right size for your project.

A ball screw’s size depends on its application and performance requirements. Some types have small diameters and fine leads, while others feature large diameters. High precision applications often require miniature ball screws. Some manufacturers even offer compact ball screws with a smaller outer diameter. The latter is commonly found in miniature designs and feature diameters up to 25 mm. However, this doesn’t mean that a smaller diameter means less accuracy. Regardless of the size, you’ll want to make sure to select a screw that will meet your requirements.

The screw’s root diameter is a critical measurement in determining critical speed and column load calculations. A ball screw’s minor diameter is the minimum dimension of the screw shaft at the bottom of the ball grooves. In addition, the idler ball is a necessary component of a ball screw. It prevents friction between the load and idler balls, but does not carry the load itself. Likewise, the non-operating load capacity should be large enough to prevent the balls from brinelling and plastic deformation.

The characteristic speed is the rotational speed at which the ball screw begins to vibrate due to dynamic load. Inch/imperial screws are specified for one million revolutions, while metric screw has a specific limit for 1 million inches of linear travel. Various manufacturing processes have their own ways to calculate the useful life of ball screw assemblies. For example, Precision Grinding produces the lowest lead errors. In addition, the life of a ball screw depends on the length of the screw and the mounting support for the end bearings.

Maintenance

It is critical to regularly perform PM on your ball screw assemblies to ensure optimal performance. A dirty ball screw assembly will result in poor performance and faster wear, so removing dirt from the nut and shaft is a good idea. If there are problems with the ball nut, the lubricant inside can become stripped or the nut can become dirty due to chemical exposure. You should also check for oxidation or corrosion on the contact surfaces of the ball screw, and replace it if necessary.

The first sign of a deteriorating ball screw is excessive vibration. This may be caused by a bent screw shaft or misaligned bearing housings. If it makes noise when running, this may be due to excessive build-up or a broken return tube. Other issues may be caused by endplay in support bearings or excessive preload or improper lubrication. If any of these problems are found, it is essential to perform regular maintenance on the ball screw to prolong its life.

Getting regular maintenance on the ball screw assembly is important. If the screw is not properly maintained, it may wear out prematurely. If this happens, you can contact a ball screw repair service. CZPT International, Inc., a leading supplier of industrial parts, can help you get the screw back into optimal working order or find a new one. A ball screw repair company can help you avoid the inconvenience of downtime and maximize your productivity.

It is essential to properly lubricate a ball screw assembly in order to prolong its life. Lubrication can prevent corrosion and increase the life of the screw by 85 percent. It is important to remember that the type of lubricant you use should correspond to the load applied to the assembly. Lubrication should also be done at regular intervals. Once you’ve established the right amount of lubrication, you can then apply it on the screw.

China OEM Good Service Custom Made Cast Agricultural Machinery Parts near me manufacturer

Product Description

Good service custom made cast agricultural machinery parts

|

R&D |

Softward: Solidworks, CAD, Procast, UG Development cycle of samples: 25-35 days |

|

Materials |

Stainless steel: 304/304L, 316/316L, 410/416 etc |

|

Technical Parameter |

Part weight: 2g to 30kgs |

|

Heat treatment |

Normalzing, Tempering, Quenching, Annealing, Quenching & Tempering, Caburization, Solution treatment. |

|

Surface treatment |

Polishing, bead blasting, zinc plating, hot dip galvanized, nickel plating, passivation, Electro-polising, mirror polishing, Brush polishing, PE coating, Powder coating, etc |

|

Inspection |

Cleanliness inspection, X-Ray radiographic inspection, CMM inspection |

|

Production capacity |

More than 120 tons per month |

|

Quality Certificates |

ISO9001; ISO14001 |

Advantages of Stainless Steel Castings

Stainless steel investment castings are used across a wide range of industry sectors for the following reasons:

- Excellent Corrosion Resistance: Chromium is used as an alloying element in stainless steel which helps improve its anti-corrosive properties. Unlike carbon and alloy steel, stainless steel castings require little or no additional surface finishing. This 1 reason why stainless steel investment cast parts are used in industrial components such as valves, pumps, and other parts where corrosion resistance is critical.

- Exceptional Visual Quality: Grade A visual appearance is possible for investment cast parts that require high visual quality.

- Surface Finishes: 120 RMS or better is easily achieve.

- Close Tolerances: ±.005 inch per inch tolerance levels can be achieved

- Near Net Shape Parts: Avoid long run time machine parts using near net investment cast parts.

Production Process

- Creating the “pattern”(i.e. a replica) of the part that’s to be cast by injecting wax into a die. This process is also used for die casting. Usually, the pattern is created as 1 piece.

- Compiling potentially several wax patterns into a completed assembly known as a gating system or “tree”. This form allows molten metal to flow into the CZPT cavity at a later stage.

- Immersing the assembly in high-grade ceramic slurry(known as the investment stage).

- Building up an additional coating of coarse ceramic particles up to 10mm thick while the assembly is still wet.

- Melting the wax from the dry CZPT to leave a thin-walled and hollow ceramic shell.

- Firing the moulds to remove any last vestiges of wax and add durability to the final mould. This can necessitate temperatures of 1000°C.

- Pouring molten metal within the still-heated moulds. A heated CZPT is used to instil better dimensional accuracy, with tolerances of as low as .076mm enabled.

- Breaking or cutting the cooled shell mould open to reveal the casting.

- Cutting each pattern off the tree

- Finishing the final part using fettling, grinding, sandblasting, heat treatment and other testing or surface finishing processe.

Latest News!!

New wax injection machine set up finished. Max-pressure is 35 tons,wax pattern largest size is 800*600 mm.

It’s the biggest wax injection machine in China.

With the help of this machine,we are CZPT to cast big steel parts for our customers by silical sol investment casting way.

Secondary Operations and Treatment of Investment Castings We Offer

|

Polished zinc plating, nickel plating, electroplating, Chrome plating |

|

|

Anodizing, phosphating, acid treatment, polishing |

|

|

High precision CNC machining |

|

|

Broaching, milling, drilling, tapping |

|

|

Surface grinding, sand blasting, powder coating |

|

|

Heat treatment |

Q1: What is our payment term?

A:T/T, Paypal.

Q2: How can we quote for you?

A: Please email us enquiry with all technical drawings you have, such as material grade, tolerance, mechanical

properties, heat treatment, requirements, etc. Our specialized engineers will check and quote for you within 24 hours.

Q3: Which product are often processed by your company ?

A: Auto parts,machinery part, marine part, Kitchen parts, Agricultural parts.

Q4: Which material are often used ?

A: Stainless steel. alloy steel, carbon steel, aluminum, copper.

Q5: Which finish you can provide ?

A:Sand blasting, Tumbling, Polishinh, Electro-polishing, Mirror Polishing, Powder coating, Electrophoresis, ETC.

Q6: What is the MOQ ?

A: Based on the product, normal 100 pcs.

Q7: Can we make the samples?

A: Is Available, 15-20days for sampling.

Q8: How about for the lead time?

A: Normally about 35 days for mass production, pls inform us if it is urgent order.

Lead Screws and Clamp Style Collars

If you have a lead screw, you’re probably interested in learning about the Acme thread on this type of shaft. You might also be interested in finding out about the Clamp style collars and Ball screw nut. But before you buy a new screw, make sure you understand what the terminology means. Here are some examples of screw shafts:

Acme thread

The standard ACME thread on a screw shaft is made of a metal that is resistant to corrosion and wear. It is used in a variety of applications. An Acme thread is available in a variety of sizes and styles. General purpose Acme threads are not designed to handle external radial loads and are supported by a shaft bearing and linear guide. Their design is intended to minimize the risk of flank wedging, which can cause friction forces and wear. The Centralizing Acme thread standard caters to applications without radial support and allows the thread to come into contact before its flanks are exposed to radial loads.

The ACME thread was first developed in 1894 for machine tools. While the acme lead screw is still the most popular screw in the US, European machines use the Trapezoidal Thread (Metric Acme). The acme thread is a stronger and more resilient alternative to square threads. It is also easier to cut than square threads and can be cut by using a single-point threading die.

Similarly to the internal threads, the metric versions of Acme are similar to their American counterparts. The only difference is that the metric threads are generally wider and are used more frequently in industrial settings. However, the metric-based screw threads are more common than their American counterparts worldwide. In addition, the Acme thread on screw shafts is used most often on external gears. But there is still a small minority of screw shafts that are made with a metric thread.

ACME screws provide a variety of advantages to users, including self-lubrication and reduced wear and tear. They are also ideal for vertical applications, where a reduced frictional force is required. In addition, ACME screws are highly resistant to back-drive and minimize the risk of backlash. Furthermore, they can be easily checked with readily available thread gauges. So, if you’re looking for a quality ACME screw for your next industrial project, look no further than ACME.

Lead screw coatings

The properties of lead screw materials affect their efficiency. These materials have high anti-corrosion, thermal resistance, and self-lubrication properties, which eliminates the need for lubrication. These coating materials include polytetrafluoroethylene (PFE), polyether ether ketone (PEK), and Vespel. Other desirable properties include high tensile strength, corrosion resistance, and rigidity.

The most common materials for lead screws are carbon steel, stainless steel, and aluminum. Lead screw coatings can be PTFE-based to withstand harsh environments and remove oil and grease. In addition to preventing corrosion, lead screw coatings improve the life of polymer parts. Lead screw assembly manufacturers offer a variety of customization options for their lead screw, including custom-molded nuts, thread forms, and nut bodies.

Lead screws are typically measured in rpm, or revolutions per minute. The PV curve represents the inverse relationship between contact surface pressure and sliding velocity. This value is affected by the material used in the construction of the screw, lubrication conditions, and end fixity. The critical speed of lead screws is determined by their length and minor diameter. End fixity refers to the support for the screw and affects its rigidity and critical speed.

The primary purpose of lead screws is to enable smooth movement. To achieve this, lead screws are usually preloaded with axial load, enabling consistent contact between a screw’s filets and nuts. Lead screws are often used in linear motion control systems and feature a large area of sliding contact between male and female threads. Lead screws can be manually operated or mortised and are available in a variety of sizes and materials. The materials used for lead screws include stainless steel and bronze, which are often protected by a PTFE type coating.

These screws are made of various materials, including stainless steel, bronze, and various plastics. They are also made to meet specific requirements for environmental conditions. In addition to lead screws, they can be made of stainless steel, aluminum, and carbon steel. Surface coatings can improve the screw’s corrosion resistance, while making it more wear resistant in tough environments. A screw that is coated with PTFE will maintain its anti-corrosion properties even in tough environments.

Clamp style collars

The screw shaft clamp style collar is a basic machine component, which is attached to the shaft via multiple screws. These collars act as mechanical stops, load bearing faces, or load transfer points. Their simple design makes them easy to install. This article will discuss the pros and cons of this style of collar. Let’s look at what you need to know before choosing a screw shaft clamp style collar. Here are some things to keep in mind.

Clamp-style shaft collars are a versatile mounting option for shafts. They have a recessed screw that fully engages the thread for secure locking. Screw shaft clamp collars come in different styles and can be used in both drive and power transmission applications. Listed below are the main differences between these 2 styles of collars. They are compatible with all types of shafts and are able to handle axial loads of up to 5500 pounds.

Clamp-style shaft collars are designed to prevent the screw from accidentally damaging the shaft when tightened. They can be tightened with a set screw to counteract the initial clamping force and prevent the shaft from coming loose. However, when tightening the screw, you should use a torque wrench. Using a set screw to tighten a screw shaft collar can cause it to warp and reduce the surface area that contacts the shaft.

Another key advantage to Clamp-style shaft collars is that they are easy to install. Clamp-style collars are available in one-piece and two-piece designs. These collars lock around the shaft and are easy to remove and install. They are ideal for virtually any shaft and can be installed without removing any components. This type of collar is also recommended for those who work on machines with sensitive components. However, be aware that the higher the OD, the more difficult it is to install and remove the collar.

Screw shaft clamp style collars are usually one-piece. A two-piece collar is easier to install than a one-piece one. The two-piece collars provide a more effective clamping force, as they use the full seating torque. Two-piece collars have the added benefit of being easy to install because they require no tools to install. You can disassemble one-piece collars before installing a two-piece collar.

Ball screw nut

The proper installation of a ball screw nut requires that the nut be installed on the center of the screw shaft. The return tubes of the ball nut must be oriented upward so that the ball nut will not overtravel. The adjusting nut must be tightened against a spacer or spring washer, then the nut is placed on the screw shaft. The nut should be rotated several times in both directions to ensure that it is centered.

Ball screw nuts are typically manufactured with a wide range of preloads. Large preloads are used to increase the rigidity of a ball screw assembly and prevent backlash, the lost motion caused by a clearance between the ball and nut. Using a large amount of preload can lead to excessive heat generation. The most common preload for ball screw nuts is 1 to 3%. This is usually more than enough to prevent backlash, but a higher preload will increase torque requirements.

The diameter of a ball screw is measured from its center, called the ball circle diameter. This diameter represents the distance a ball will travel during 1 rotation of the screw shaft. A smaller diameter means that there are fewer balls to carry the load. Larger leads mean longer travels per revolution and higher speeds. However, this type of screw cannot carry a greater load capacity. Increasing the length of the ball nut is not practical, due to manufacturing constraints.

The most important component of a ball screw is a ball bearing. This prevents excessive friction between the ball and the nut, which is common in lead-screw and nut combinations. Some ball screws feature preloaded balls, which avoid “wiggle” between the nut and the ball. This is particularly desirable in applications with rapidly changing loads. When this is not possible, the ball screw will experience significant backlash.

A ball screw nut can be either single or multiple circuits. Single or multiple-circuit ball nuts can be configured with 1 or 2 independent closed paths. Multi-circuit ball nuts have 2 or more circuits, making them more suitable for heavier loads. Depending on the application, a ball screw nut can be used for small clearance assemblies and compact sizes. In some cases, end caps and deflectors may be used to feed the balls back to their original position.

China manufacturer Power Tiller Walking Tractor Agricultural Machinery Parts with Best Sales

Product Description

Professional in Agricultural Machinery & Accessories in China for 15 years

Our 1GK-series rotary tillers are carefully designed according to different soil qualities. They can be used with various types of tractors for rotary tillage, crushing and stubble burying operations. There is no ridge, the surface is fine and smooth, and the stubble burial rate reaches more than 90%.

The 1GK series rotary tiller have a multi-functional and high-efficiency supporting machine promoted by governments at all levels. The through-shaft type can be used for positive and negative rotary tillage, for different users to choose,and has won many national patents.

Note: Samples under USD 200 are free to provide. We have advantage on agricultural machinery parts. We have more than 9,000 series of conponents of many machines.

For samples, normally we use DHL, fedex, UPS, TNT andEMS. If you have inquyiry, welcome to contact with us.

Guide to Drive Shafts and U-Joints

If you’re concerned about the performance of your car’s driveshaft, you’re not alone. Many car owners are unaware of the warning signs of a failed driveshaft, but knowing what to look for can help you avoid costly repairs. Here is a brief guide on drive shafts, U-joints and maintenance intervals. Listed below are key points to consider before replacing a vehicle driveshaft.

Symptoms of Driveshaft Failure

Identifying a faulty driveshaft is easy if you’ve ever heard a strange noise from under your car. These sounds are caused by worn U-joints and bearings supporting the drive shaft. When they fail, the drive shafts stop rotating properly, creating a clanking or squeaking sound. When this happens, you may hear noise from the side of the steering wheel or floor.

In addition to noise, a faulty driveshaft can cause your car to swerve in tight corners. It can also lead to suspended bindings that limit overall control. Therefore, you should have these symptoms checked by a mechanic as soon as you notice them. If you notice any of the symptoms above, your next step should be to tow your vehicle to a mechanic. To avoid extra trouble, make sure you’ve taken precautions by checking your car’s oil level.

In addition to these symptoms, you should also look for any noise from the drive shaft. The first thing to look for is the squeak. This was caused by severe damage to the U-joint attached to the drive shaft. In addition to noise, you should also look for rust on the bearing cap seals. In extreme cases, your car can even shudder when accelerating.

Vibration while driving can be an early warning sign of a driveshaft failure. Vibration can be due to worn bushings, stuck sliding yokes, or even springs or bent yokes. Excessive torque can be caused by a worn center bearing or a damaged U-joint. The vehicle may make unusual noises in the chassis system.

If you notice these signs, it’s time to take your car to a mechanic. You should check regularly, especially heavy vehicles. If you’re not sure what’s causing the noise, check your car’s transmission, engine, and rear differential. If you suspect that a driveshaft needs to be replaced, a certified mechanic can replace the driveshaft in your car.

Drive shaft type

Driveshafts are used in many different types of vehicles. These include four-wheel drive, front-engine rear-wheel drive, motorcycles and boats. Each type of drive shaft has its own purpose. Below is an overview of the 3 most common types of drive shafts:

The driveshaft is a circular, elongated shaft that transmits torque from the engine to the wheels. Drive shafts often contain many joints to compensate for changes in length or angle. Some drive shafts also include connecting shafts and internal constant velocity joints. Some also include torsional dampers, spline joints, and even prismatic joints. The most important thing about the driveshaft is that it plays a vital role in transmitting torque from the engine to the wheels.

The drive shaft needs to be both light and strong to move torque. While steel is the most commonly used material for automotive driveshafts, other materials such as aluminum, composites, and carbon fiber are also commonly used. It all depends on the purpose and size of the vehicle. Precision Manufacturing is a good source for OEM products and OEM driveshafts. So when you’re looking for a new driveshaft, keep these factors in mind when buying.

Cardan joints are another common drive shaft. A universal joint, also known as a U-joint, is a flexible coupling that allows 1 shaft to drive the other at an angle. This type of drive shaft allows power to be transmitted while the angle of the other shaft is constantly changing. While a gimbal is a good option, it’s not a perfect solution for all applications.

CZPT, Inc. has state-of-the-art machinery to service all types of drive shafts, from small cars to race cars. They serve a variety of needs, including racing, industry and agriculture. Whether you need a new drive shaft or a simple adjustment, the staff at CZPT can meet all your needs. You’ll be back on the road soon!

U-joint

If your car yoke or u-joint shows signs of wear, it’s time to replace them. The easiest way to replace them is to follow the steps below. Use a large flathead screwdriver to test. If you feel any movement, the U-joint is faulty. Also, inspect the bearing caps for damage or rust. If you can’t find the u-joint wrench, try checking with a flashlight.

When inspecting U-joints, make sure they are properly lubricated and lubricated. If the joint is dry or poorly lubricated, it can quickly fail and cause your car to squeak while driving. Another sign that a joint is about to fail is a sudden, excessive whine. Check your u-joints every year or so to make sure they are in proper working order.

Whether your u-joint is sealed or lubricated will depend on the make and model of your vehicle. When your vehicle is off-road, you need to install lubricable U-joints for durability and longevity. A new driveshaft or derailleur will cost more than a U-joint. Also, if you don’t have a good understanding of how to replace them, you may need to do some transmission work on your vehicle.

When replacing the U-joint on the drive shaft, be sure to choose an OEM replacement whenever possible. While you can easily repair or replace the original head, if the u-joint is not lubricated, you may need to replace it. A damaged gimbal joint can cause problems with your car’s transmission or other critical components. Replacing your car’s U-joint early can ensure its long-term performance.

Another option is to use 2 CV joints on the drive shaft. Using multiple CV joints on the drive shaft helps you in situations where alignment is difficult or operating angles do not match. This type of driveshaft joint is more expensive and complex than a U-joint. The disadvantages of using multiple CV joints are additional length, weight, and reduced operating angle. There are many reasons to use a U-joint on a drive shaft.

maintenance interval

Checking U-joints and slip joints is a critical part of routine maintenance. Most vehicles are equipped with lube fittings on the driveshaft slip joint, which should be checked and lubricated at every oil change. CZPT technicians are well-versed in axles and can easily identify a bad U-joint based on the sound of acceleration or shifting. If not repaired properly, the drive shaft can fall off, requiring expensive repairs.

Oil filters and oil changes are other parts of a vehicle’s mechanical system. To prevent rust, the oil in these parts must be replaced. The same goes for transmission. Your vehicle’s driveshaft should be inspected at least every 60,000 miles. The vehicle’s transmission and clutch should also be checked for wear. Other components that should be checked include PCV valves, oil lines and connections, spark plugs, tire bearings, steering gearboxes and brakes.

If your vehicle has a manual transmission, it is best to have it serviced by CZPT’s East Lexington experts. These services should be performed every 2 to 4 years or every 24,000 miles. For best results, refer to the owner’s manual for recommended maintenance intervals. CZPT technicians are experienced in axles and differentials. Regular maintenance of your drivetrain will keep it in good working order.