Product Description

HangZhou CZPT hardware machinery co., LTD mainly for the domestic and foreign customers to provide precision metal parts of intelligent manufacturing solutions, the company was founded in 2008, currently has more than 60 units, all kinds of high precision sophisticated equipment manufacturing system more than 80 employees, including senior technical personnel more than 40 people, and signed with the several technical and training center, talent directional delivery plan.

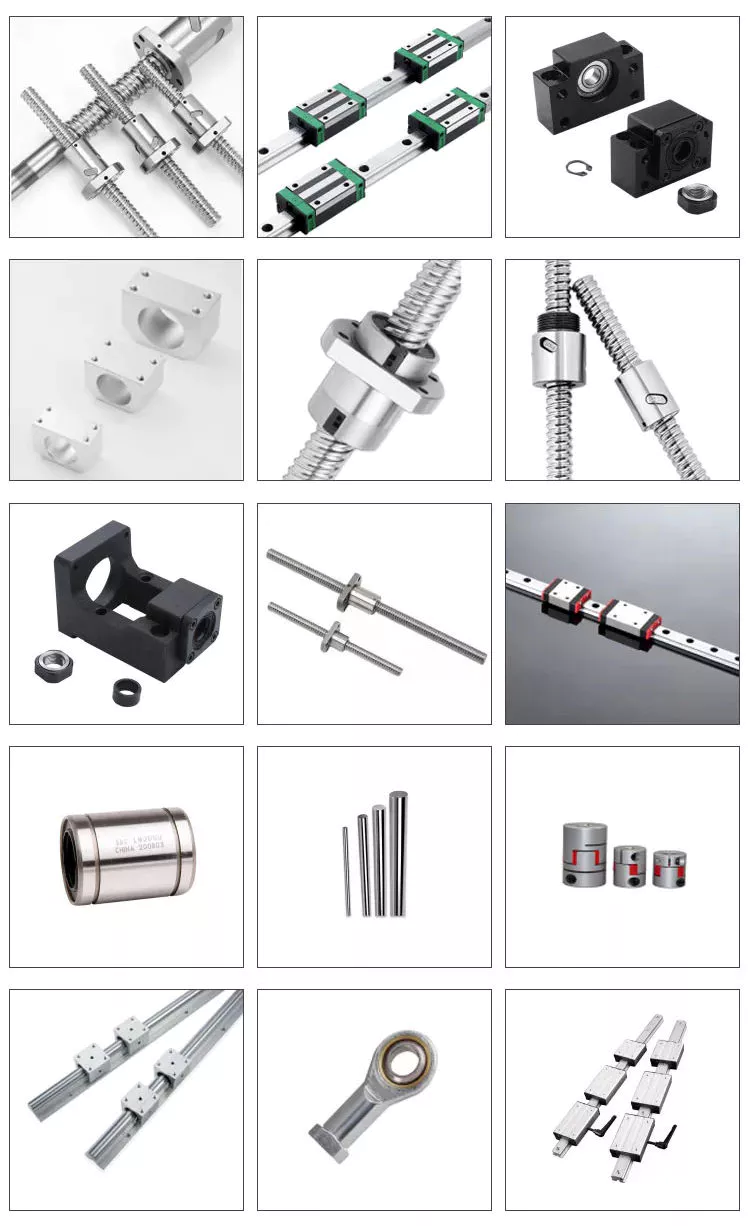

The company’s business involves the precision parts and hardware processing of auto parts, 3C automation equipment, aerospace, engineering machinery, medical, food, new energy battery equipment, instruments and meters, precision instruments, hardware tools and other industries. At the same time, we also provide customers with precision fixture, fixture, mold parts design and manufacturing, special material parts processing (such as ceramics, hard alloy) and automation equipment design, installation, commissioning, and production equipment maintenance, improvement and other related business.

In terms of production, we comply with ISO9001: 2015 quality management system, each link of production strictly control, to ensure product performance and quality, at the same time the company also set up the system perfect, the internationalization of scientific and effective information security management system, from the professional and authority level for the customer to provide information security, let the customer’s product won’t appear the leaks of security risks, make guaranteed delivery cycle.

Companies adhering to the “heavy quality, honest, responsible” corporate purposes, with “customer first, in the victory in technology, efficiency and win in the service” business philosophy, in the “fine management, skilled, profound culture, team capable” of the “four” management policy guidance, the company has been in the precision parts processing industry has reached the industry leading level.

At present, the company has served nearly 100 customers, 80% of the customers are well-known enterprises in the industry, at the same time, we have a perfect after-sales service system in the industry, continue to use a solid technical basis and strict scientific management system, continuous improvement, beyond customer satisfaction, so that customers feel comfortable before cooperation, after cooperation.

| Service | service item |

| Product Service | CNC turning parts/ Machining |

| CNC milling parts machining | |

| simple CNC turning-milling product | |

| 4-Axis turning-milling combined machining product | |

| high precision 5-Axis turning-milling combined machining product | |

| customzied Machine tools, metal machining – parts and accessories | |

| Precison CNC PRECISION AUTOMATIC LATHE product | |

| CNC Swiss screw machine parts | |

| Centerless grinding services | |

| Product quality Inspection Service | Inspection Report First Article Inspection |

A: We are a professional manufacturer of precision parts.

Q2. What are your payment terms?

A: T/T 50% is used as a deposit, and the remaining 50% is used as a copy of BL.

Q3. What are your delivery terms?

A: EXW, FOB, CFR, CIF, DDU.

Q4. How is your delivery time?

A: We can ship the order within 3-30 days, depending on the quantity.

Q5. Can you produce according to samples?

A: Yes, we can produce according to your samples or technical drawings. We can make new molds.

Q6. What is your sample policy?

A: If we have stock, we can provide samples, but the customer must pay the sample cost and

Courier fees.

Q7. Do you test all the goods before delivery?

A: Yes, we have testing machines and QC workers to do the testing.

Q8: How do you make our business a long-term good cooperative relationship?

Answer: 1. We maintain excellent quality and competitive prices to ensure that our customers benefit;

2. We respect every customer as our friend, we do business sincerely, make friends,

No matter where they are from.

What is a drive shaft?

If you notice a clicking noise while driving, it is most likely the driveshaft. An experienced auto mechanic will be able to tell you if the noise is coming from both sides or from 1 side. If it only happens on 1 side, you should check it. If you notice noise on both sides, you should contact a mechanic. In either case, a replacement driveshaft should be easy to find.

The drive shaft is a mechanical part

A driveshaft is a mechanical device that transmits rotation and torque from the engine to the wheels of the vehicle. This component is essential to the operation of any driveline, as the mechanical power from the engine is transmitted to the PTO (power take-off) shaft, which hydraulically transmits that power to connected equipment. Different drive shafts contain different combinations of joints to compensate for changes in shaft length and angle. Some types of drive shafts include connecting shafts, internal constant velocity joints, and external fixed joints. They also contain anti-lock system rings and torsional dampers to prevent overloading the axle or causing the wheels to lock.

Although driveshafts are relatively light, they need to handle a lot of torque. Torque applied to the drive shaft produces torsional and shear stresses. Because they have to withstand torque, these shafts are designed to be lightweight and have little inertia or weight. Therefore, they usually have a joint, coupling or rod between the 2 parts. Components can also be bent to accommodate changes in the distance between them.

The drive shaft can be made from a variety of materials. The most common material for these components is steel, although alloy steels are often used for high-strength applications. Alloy steel, chromium or vanadium are other materials that can be used. The type of material used depends on the application and size of the component. In many cases, metal driveshafts are the most durable and cheapest option. Plastic shafts are used for light duty applications and have different torque levels than metal shafts.

It transfers power from the engine to the wheels

A car’s powertrain consists of an electric motor, transmission, and differential. Each section performs a specific job. In a rear-wheel drive vehicle, the power generated by the engine is transmitted to the rear tires. This arrangement improves braking and handling. The differential controls how much power each wheel receives. The torque of the engine is transferred to the wheels according to its speed.

The transmission transfers power from the engine to the wheels. It is also called “transgender”. Its job is to ensure power is delivered to the wheels. Electric cars cannot drive themselves and require a gearbox to drive forward. It also controls how much power reaches the wheels at any given moment. The transmission is the last part of the power transmission chain. Despite its many names, the transmission is the most complex component of a car’s powertrain.

The driveshaft is a long steel tube that transmits mechanical power from the transmission to the wheels. Cardan joints connect to the drive shaft and provide flexible pivot points. The differential assembly is mounted on the drive shaft, allowing the wheels to turn at different speeds. The differential allows the wheels to turn at different speeds and is very important when cornering. Axles are also important to the performance of the car.

It has a rubber boot that protects it from dust and moisture

To keep this boot in good condition, you should clean it with cold water and a rag. Never place it in the dryer or in direct sunlight. Heat can deteriorate the rubber and cause it to shrink or crack. To prolong the life of your rubber boots, apply rubber conditioner to them regularly. Indigenous peoples in the Amazon region collect latex sap from the bark of rubber trees. Then they put their feet on the fire to solidify the sap.

it has a U-shaped connector

The drive shaft has a U-joint that transfers rotational energy from the engine to the axle. Defective gimbal joints can cause vibrations when the vehicle is in motion. This vibration is often mistaken for a wheel balance problem. Wheel balance problems can cause the vehicle to vibrate while driving, while a U-joint failure can cause the vehicle to vibrate when decelerating and accelerating, and stop when the vehicle is stopped.

The drive shaft is connected to the transmission and differential using a U-joint. It allows for small changes in position between the 2 components. This prevents the differential and transmission from remaining perfectly aligned. The U-joint also allows the drive shaft to be connected unconstrained, allowing the vehicle to move. Its main purpose is to transmit electricity. Of all types of elastic couplings, U-joints are the oldest.

Your vehicle’s U-joints should be inspected at least twice a year, and the joints should be greased. When checking the U-joint, you should hear a dull sound when changing gears. A clicking sound indicates insufficient grease in the bearing. If you hear or feel vibrations when shifting gears, you may need to service the bearings to prolong their life.

it has a slide-in tube

The telescopic design is a modern alternative to traditional driveshaft designs. This innovative design is based on an unconventional design philosophy that combines advances in material science and manufacturing processes. Therefore, they are more efficient and lighter than conventional designs. Slide-in tubes are a simple and efficient design solution for any vehicle application. Here are some of its benefits. Read on to learn why this type of shaft is ideal for many applications.

The telescopic drive shaft is an important part of the traditional automobile transmission system. These driveshafts allow linear motion of the 2 components, transmitting torque and rotation throughout the vehicle’s driveline. They also absorb energy if the vehicle collides. Often referred to as foldable driveshafts, their popularity is directly dependent on the evolution of the automotive industry.

It uses a bearing press to replace worn or damaged U-joints

A bearing press is a device that uses a rotary press mechanism to install or remove worn or damaged U-joints from a drive shaft. With this tool, you can replace worn or damaged U-joints in your car with relative ease. The first step involves placing the drive shaft in the vise. Then, use the 11/16″ socket to press the other cup in far enough to install the clips. If the cups don’t fit, you can use a bearing press to remove them and repeat the process. After removing the U-joint, use a grease nipple Make sure the new grease nipple is installed correctly.

Worn or damaged U-joints are a major source of driveshaft failure. If 1 of them were damaged or damaged, the entire driveshaft could dislocate and the car would lose power. Unless you have a professional mechanic doing the repairs, you will have to replace the entire driveshaft. Fortunately, there are many ways to do this yourself.

If any of these warning signs appear on your vehicle, you should consider replacing the damaged or worn U-joint. Common symptoms of damaged U-joints include rattling or periodic squeaking when moving, rattling when shifting, wobbling when turning, or rusted oil seals. If you notice any of these symptoms, take your vehicle to a qualified mechanic for a full inspection. Neglecting to replace a worn or damaged u-joint on the driveshaft can result in expensive and dangerous repairs and can cause significant damage to your vehicle.